TFXH Series Circulating Air Separator

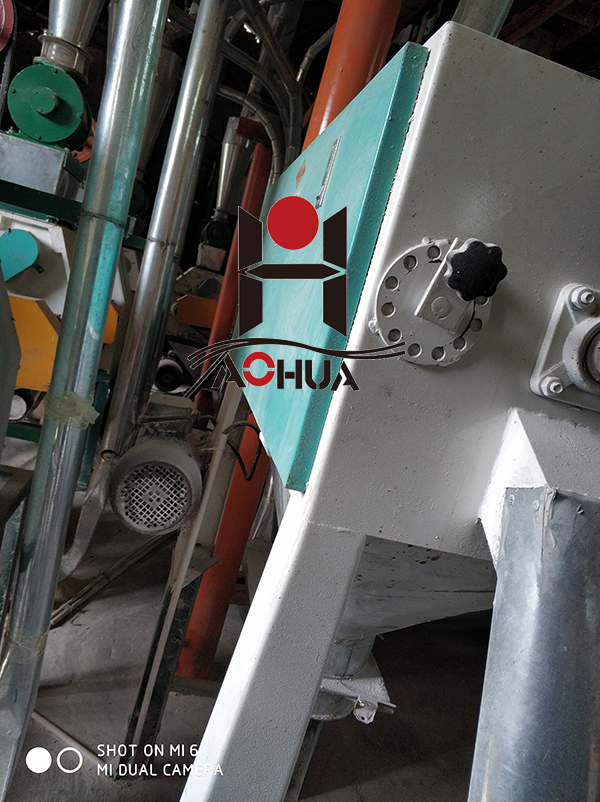

TFXH Series Circulating Air Separator is a highly efficient and energy-saving equipment designed for the removal of lightweight impurities (e.g., dust, husks, and chaff) from grains such as wheat, corn, barley, and oilseeds. Widely adopted in grain storage facilities, flour mills, feed factories, and oil processing plants, this equipment leverages closed-loop airflow technology to optimize resource utilization while minimizing environmental impact.

The TFXH separator operates on a closed-loop airflow system, eliminating the need for external ventilation networks. Its workflow can be summarized as follows:

1.Feeding and Initial Separation

Grains enter the feed hopper, where a rotating roller feeder ensures controlled material flow, preventing external air infiltration.

The grains are then directed into the aspiration channel, where a high-speed centrifugal fan generates airflow. Lightweight impurities are lifted by the airflow and carried into the separation zone.

2.Centrifugal Separation

In the separation zone, impurities and airflow enter a cyclone chamber. Centrifugal force and gravity cause the impurities to settle into a dust collection chamber, while purified air is recirculated via the return duct.

A screw conveyor (auger) transports settled impurities to a pressure-controlled discharge valve, ensuring continuous operation without blockages.

3.Grain Output

Purified grains exit through a gravity-operated gate at the bottom of the separator, maintaining a closed-loop system with minimal energy loss.

Technical Features

1.Closed-Loop Airflow: Reduces fresh air intake by 80%, lowering energy consumption and dust emissions.

2.Axial Pressure Discharge Mechanism: Prevents jamming of lightweight impurities in the screw conveyor.

3.Adjustable Airflow: Customizable wind speed and separation efficiency via control panels.

Circulating Air Separator Technical Parameter:

| Model | Capacity (t/h) | Power(kw) | Air Volume(m³/min) | Size(mm) | ||

| Cleaning | Precleaning | Cleaning | Precleaning | |||

| TFXH60 | 9 | 40 | 0.75+2.2 | 240 | 480 | 1280*1050*1730 |

| TFXH80 | 12 | 50 | 0.75+2.2 | 300 | 550 | 1480*1050*1730 |

| TFXH100 | 16 | 65 | 0.75+2.2 | 360 | 600 | 1680*1050*1730 |

| TFXH125 | 20 | 83 | 0.75+2.2 | 400 | 650 | 1930*1050*1730 |

| TFXH150 | 24 | 100 | 1.1+2.2*2 | 480 | 720 | 2630*1050*1730 |

| TFXH180 | 28 | 105 | 1.1+3*2 | 520 | 760 | 3130*1050*1730 |

| TFXH200 | 32 | 120 | 1.1+3*2 | 550 | 800 | 3130*1050*1730 |