- Whatsapp:+86-13949074923

- Email: Dianaguo@aohuascreeningmachine.com

product

Your Position : Home > product > Cleaning and Grading Machine

We're here to help: Easy ways to get the answers you need.

Products list

inquery

description

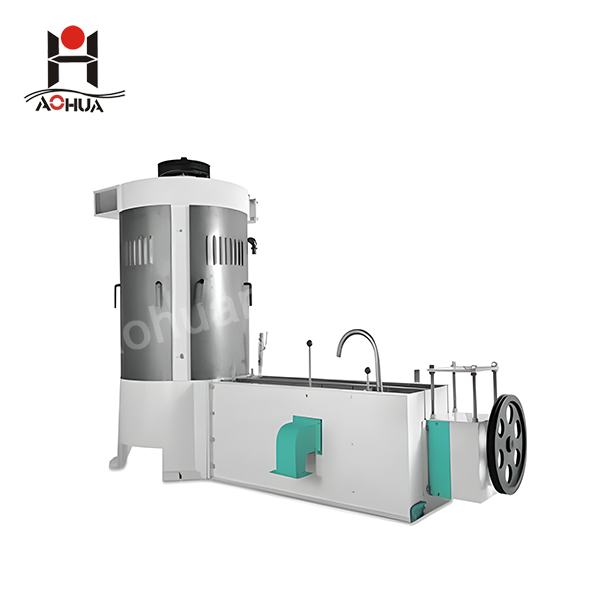

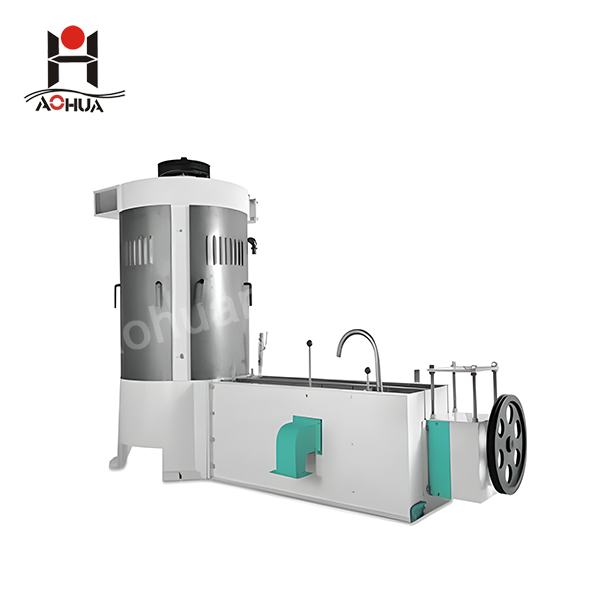

Wheat washer has good performance to remove impurity of wheat, and the wheat got into drier to drying after washing. This equipment is suitable for large, medium, and small flour mills.

1.Wheat washer upper and low base adopt high strength cast iron materials.

2.Watertight doors, screen piece, screw conveyor sink adopt stainless steel material.

3.Upper and low bearings adopt airtight dustproof special bearings and pressure bearings.

.png)

![]()

|

Type |

XMS30 |

XMS40 |

XMS50 |

XMS60 |

XMS80 |

XMS90 |

XMS105 |

|

Output(kg/h) |

600 |

1000 |

2000 |

3000 |

5000 |

6800 |

12000 |

|

Direr direction |

anticlockwise |

anticlockwise |

anticlockwise |

anticlockwise |

anticlockwise |

anticlockwise |

anticlockwise |

|

Main shaft speed(r/min) |

960 |

735 |

610 |

585 |

480 |

400 |

380 |

|

Drierpiecespecification(mm) |

300 |

400 |

500 |

600 |

800 |

900 |

1050 |

|

Screw Conveyor speed(r) |

195 |

230 |

175 |

170 |

189 |

180 |

180 |

|

Dimension(L*W*H)mm |

1500*480*1340 |

1780*630*1700 |

2160*750*1640 |

2520*880*1760 |

3000*1110*2130 |

3340*1250*2280 |

3550*1400*2550 |

|

Weight(kg) |

260 |

500 |

900 |

1300 |

2100 |

3000 |

3600 |

1. Sturdy Construction

The water tank is manufactured by high-quality and corrosion-resistant marine steel plates.

2. Convenient Maintenance

For this wheat washer, the upper and lower bearing seats are designed with oil filling ports to facilitate lubrication operations for the bearing, so the maintenance is vey simple. Meanwhile, the cleaning door is set at the lower end of the machine, and it adopts wedge-shaped iron lever for clamping. Thus, blocking problem will be solved easily if it occurs.

3. Reasonable Design

With the help of an auto-washing device, the work site will be very clean, and the moisture addition level is extremely stable.

4. Low Noise

The rotor receives dynamic balance test to improve its working precision and reduce the noise level.

5. Low Maintenance Cost

The machine door, sieve plate, angle iron and corresponding fastening components are all made from stainless steel. So, the service cycle is extended by 3-5 times, thus greatly reducing the maintenance cost of this wheat washer.

1. Seeds were feed into hopper auger. Due to the rotation of the auger, the wheat to be washed and suspended in water, then sent to the dryer box.

2. Stones and other impurities drop into the auger for their bigger gravity. By the opposite rotation of the auger, the sand fall in sand bucket under the water tank.

This machine utilizes water to wash the wheat, it may take away the sand or gemstones that is from the similar size because the wheat, clean from the ash at first glance of wheat, reduce pollution amounts of pesticide sprays and bacteria, is appropriate for big or medium -scale flour mills. The washer can function on corn, beans, sesame, etc.

.png)

![]()

1. Inner packing: Plastic film

2. Outside packing: Container/Wooden box

3. Shipping: By sea in QINGDAO port or according to your demand

Similar items MORE

Grain Cleaning MachineGrain Vibrating Screen/Grain...

.jpg)

Oatmeal Production LineThe production of oatmeal is...

Linear Vibrating ScreenLinear vibrating screen can ...

(1).jpg)

5XFZ-40Z Double Gravity Table Cleaner1.Double gravity table, Bett...

TQLS Series Combined Cleaning Stone Removal MachineCombined cleaning to stone m...

.jpg)

Plastic Vibrating ScreenPlastic vibrating sieve is m...

Please fill in your procurement needs and contact information